The construction industry has witnessed a major shift toward efficiency-driven methodologies, and prefabrication has emerged as a game-changer. Among various construction components, Mechanical, Electrical, and Plumbing (MEP) systems play a crucial role in building functionality. Traditional on-site MEP installations often face challenges such as labor shortages, scheduling conflicts, and rework due to errors. The integration of prefabrication techniques with advanced design tools, such as Building Information Modeling (BIM), has significantly improved MEP system deployment.

Prefabricated MEP components are manufactured in a controlled environment, ensuring high precision and consistency. With detailed shop drawings and pre-engineered assemblies, the prefabrication process minimizes the uncertainties of on-site construction. Contractors and engineers now rely on these drawings to coordinate complex MEP systems efficiently, reducing installation time and material wastage.

Understanding Prefabricated MEP Drawings and Their Importance

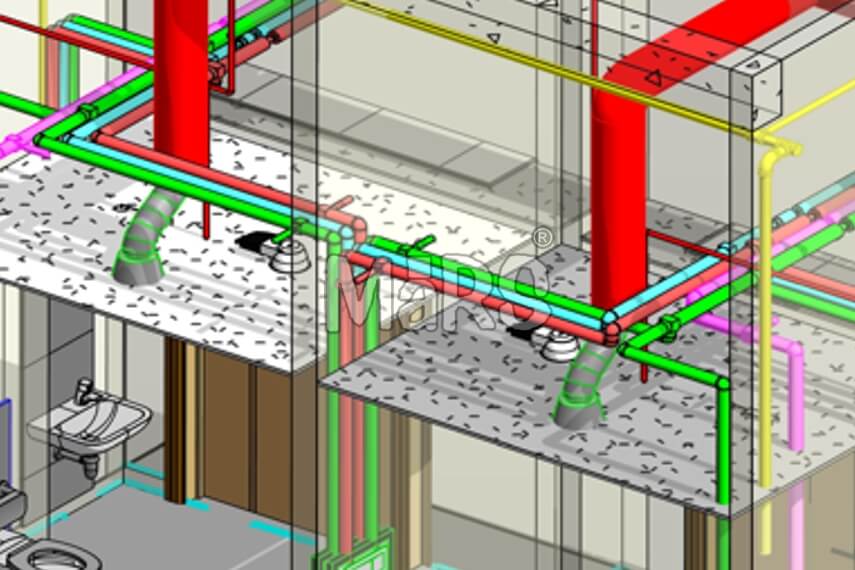

Prefabricated MEP drawings serve as detailed blueprints that guide the manufacturing of MEP components before they reach the construction site. These drawings include accurate layouts, specifications, and assembly details for HVAC ductwork, electrical conduits, and plumbing systems. Prefabricated MEP Drawing Services ensure a high level of accuracy, allowing seamless integration with structural and architectural elements, reducing clashes, and improving installation efficiency.

By adopting prefabricated MEP drawings, construction teams benefit from enhanced collaboration, streamlined workflows, and reduced project timelines. These drawings are developed using advanced CAD and BIM software, allowing for precise visualization of the MEP infrastructure. This digital approach eliminates design ambiguities and helps detect potential conflicts before manufacturing begins, thereby preventing costly errors on-site.

How Prefabricated MEP Drawings Optimize Construction Efficiency

Prefabricated MEP drawings have transformed construction by enabling modular, off-site production of critical building components. Unlike traditional MEP installations that require extensive fieldwork, prefabricated systems arrive at the site ready for quick assembly. This approach enhances efficiency in multiple ways:

- Reduced On-Site Labor Dependency – Prefabricated MEP components require fewer skilled workers on-site, addressing labor shortages and improving project scalability.

- Minimized Construction Waste – Controlled factory conditions ensure precise material utilization, significantly reducing waste.

- Faster Installation and Project Completion – Since MEP components arrive pre-assembled, installation time is drastically reduced, accelerating overall project delivery.

- Improved Safety and Quality Control – Factory-fabricated MEP elements adhere to strict quality standards, reducing errors and on-site hazards.

Given these advantages, prefabricated MEP drawings have become a critical part of modern construction planning. They not only optimize efficiency but also contribute to cost savings and sustainable building practices.

Key Components of Prefabricated MEP Drawings

Prefabricated MEP drawings encompass several essential elements that ensure accurate system fabrication and installation. These include:

- MEP Coordination Drawings: Help align MEP systems with architectural and structural elements, preventing clashes.

- Fabrication Drawings: Provide specifications for manufacturing ductwork, piping, and electrical assemblies.

- Shop Drawings: Serve as detailed blueprints for contractors and fabricators to assemble and install MEP systems.

- Spool Drawings: Break down complex piping and electrical layouts into manageable sections for easier prefabrication.

Each of these drawing types plays a crucial role in ensuring a smooth transition from design to execution, eliminating delays and enhancing construction precision.

The Role of BIM in Prefabricated MEP Drawings

Building Information Modeling (BIM) has significantly contributed to the effectiveness of prefabricated MEP drawings. By integrating BIM with prefabrication, stakeholders can visualize, analyze, and optimize MEP systems before physical fabrication begins. Some key benefits of using BIM in prefabricated MEP design include:

- Enhanced Collaboration: BIM allows seamless coordination between architects, engineers, and contractors.

- Clash Detection and Resolution: Identifies conflicts between different building systems early in the design stage.

- Data-Driven Decision-Making: Provides accurate material estimates and cost predictions, optimizing resource allocation.

- Virtual Testing and Simulations: Enables performance analysis before installation, ensuring optimal system efficiency.

With BIM, prefabricated MEP drawings become more intelligent, reducing rework and enhancing project execution.

Industries Benefiting from Prefabricated MEP Drawings

Several industries are embracing prefabricated MEP drawings due to their efficiency and cost-effectiveness. Some key sectors include:

- Healthcare: Hospitals and medical facilities require precise MEP installations to support critical systems.

- Commercial Buildings: Offices and retail spaces benefit from faster construction timelines and reduced operational disruptions.

- Industrial Facilities: Manufacturing plants and data centers demand highly coordinated MEP layouts for optimal functionality.

- Residential Construction: Multi-unit housing projects leverage prefabrication for rapid and cost-efficient development.

Challenges and Future Trends in Prefabricated MEP Drawings

While prefabrication has numerous benefits, challenges such as initial costs, design complexities, and logistics must be managed. However, with technological advancements and increased industry adoption, prefabricated MEP drawings are set to become even more refined. Future trends include:

- AI-Driven MEP Design Optimization – Artificial intelligence will enhance automation in MEP prefabrication.

- 3D Printing for MEP Components – Emerging technologies will revolutionize component manufacturing.

- Sustainable MEP Solutions – Energy-efficient and eco-friendly prefabricated MEP systems will gain traction.

Conclusion

Prefabricated MEP drawings are revolutionizing the construction landscape by enabling off-site manufacturing, reducing costs, and improving installation efficiency. With BIM integration, prefabrication offers a strategic advantage for builders, ensuring faster, safer, and more sustainable project execution. As the industry moves toward more automated and data-driven workflows, prefabricated MEP drawings will continue to drive innovation in modern construction.