As electric machines evolve to meet the demands of modern industry, the importance of efficient power distribution becomes more critical than ever. Whether in an industrial motor control system or a renewable energy inverter, the method used to transfer and distribute electricity within the machine significantly impacts its performance and safety.

Understanding Power Distribution in Electric Machines

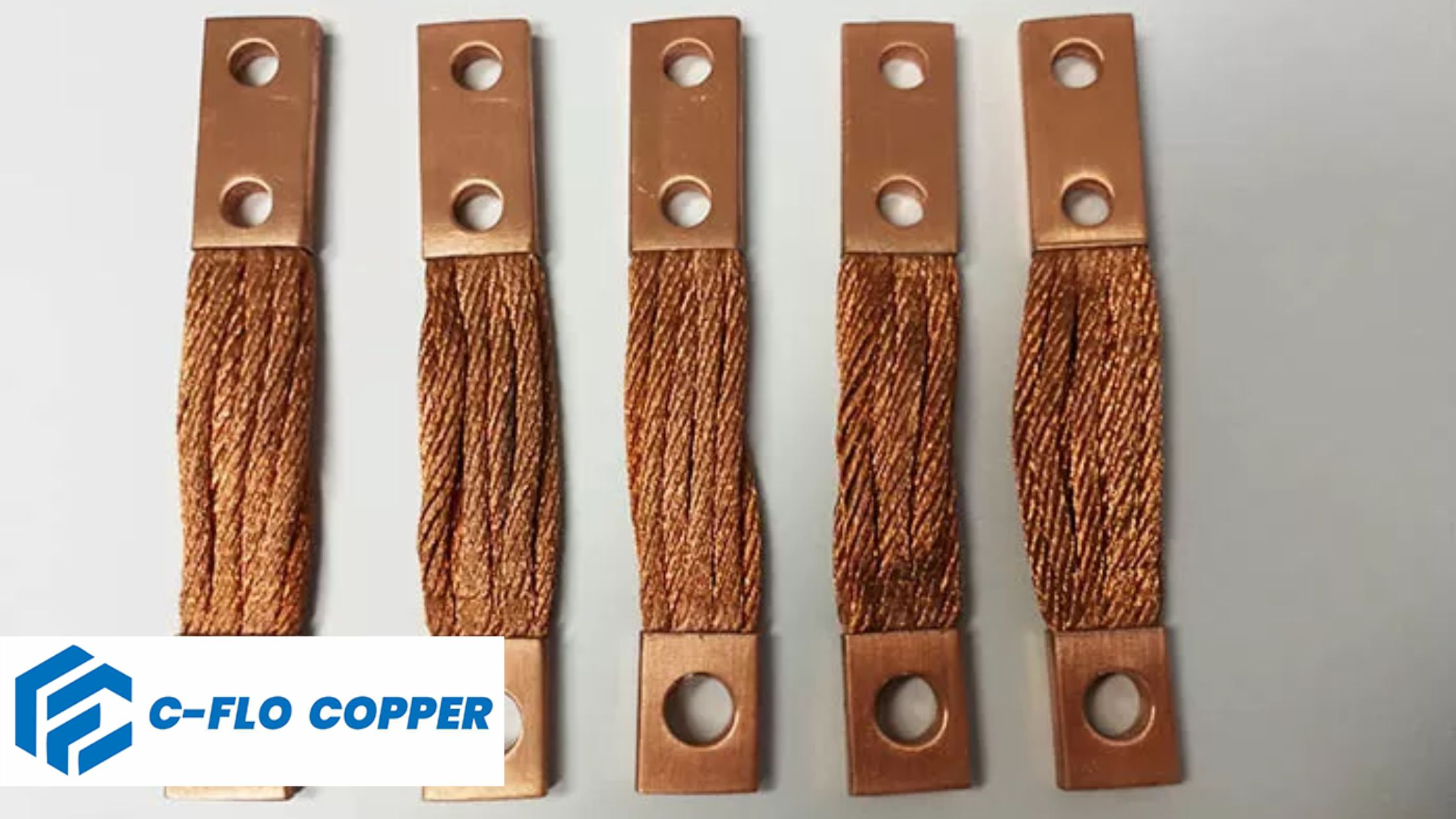

Electric machines rely on a network of conductors to carry high currents between various components. These conductors must be able to handle large loads, resist overheating, and maintain minimal energy loss. That’s where materials like copper shine—thanks to their excellent conductivity and durability under stress.

The Role of Busbars and Connectors

Busbars are the backbone of internal power distribution. A trusted copper busbars supplier ensures that these components are made with high-quality materials, precision-engineered to handle fluctuating loads and harsh operating conditions. Copper busbars not only improve current flow but also reduce wiring complexity and help with space optimization inside electrical enclosures.

On the other hand, smaller yet essential components like Copper Lugs are used to create strong, reliable connections at the cable ends. They play a vital role in preventing voltage drops and heat build-up at termination points, ensuring stable operation over long periods.

Final Thoughts

Efficient power distribution isn’t just about getting electricity from point A to B—it’s about doing it safely, reliably, and with minimal energy loss. With the right components sourced from reputable suppliers, engineers can ensure that their electric machines run smoother, longer, and more efficiently.