In the world of metal casting and foundry technology, automation and precision are the cornerstones of progress. One of the most critical components in this domain is the Pig Casting Machine, a system designed to cast molten metal into manageable, standardized ingots known as pigs. These pig ingots serve as the base material for further processing or alloying in a range of industries, from automotive to aerospace. Among the leaders in this space is Metcocal, a brand renowned for its engineering excellence, reliability, and cutting-edge innovation.

What Is a Pig Casting Machine?

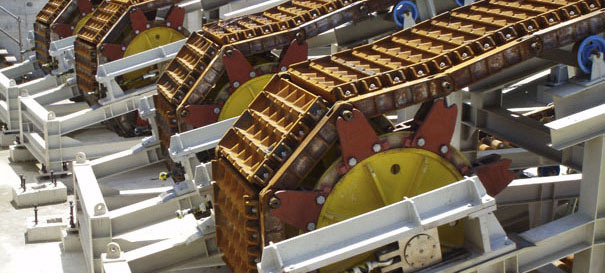

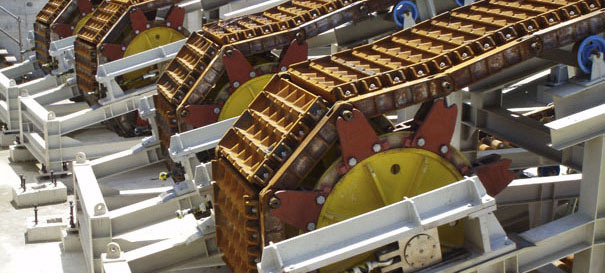

A Pig Casting Machine is a specialized system that automates the casting of molten metal into pig molds. These pigs are typically smaller than large ingots and are easier to handle, store, and re-melt. The machine takes care of the entire casting cycle — from mold preparation and metal pouring to cooling and extraction — making the process safer, faster, and more efficient.

Pig casting is especially crucial in iron and steel manufacturing, where it plays an essential role in converting molten metal from blast furnaces or electric arc furnaces into a storable form.

Why Pig Casting Matters in Modern Metallurgy

Before we dive into Metcocal’s contribution to this field, let’s understand why Pig Casting Machines are so vital to foundries and metal manufacturers:

-

Efficiency: Manual casting is time-consuming and labor-intensive. Automated machines streamline the entire process.

-

Safety: Dealing with molten metal is dangerous. Machines reduce human involvement in hazardous steps.

-

Uniformity: Machines ensure that each pig ingot is identical in size and weight, aiding in quality control.

-

Scalability: Automated systems can handle higher volumes with greater consistency, making them ideal for mass production.

Metcocal – Redefining Pig Casting Excellence

When it comes to advanced pig casting solutions, Metcocal is a brand that stands out. With decades of experience in foundry equipment manufacturing, Metcocal has consistently delivered high-performance, durable, and technologically sophisticated Pig Casting Machines tailored to the evolving needs of the industry.

Key Features of Metcocal Pig Casting Machines

Metcocal’s machines are known for their:

-

Robust Design: Built with heavy-duty materials to withstand high temperatures and abrasive environments.

-

Automation and Controls: State-of-the-art PLC systems ensure precise control over the casting process.

-

Custom Mold Design: Flexible mold sizes and patterns to suit various operational needs.

-

Cooling Systems: Efficient water or air-based cooling systems for faster solidification.

-

Ease of Maintenance: Modular components and intelligent diagnostics make upkeep straightforward.

Why Choose Metcocal?

So, what makes Metcocal the preferred choice among foundries and steel plants worldwide?

-

Proven Track Record: Trusted by hundreds of industrial clients for consistent performance.

-

Custom Engineering: Tailored solutions to match your plant’s layout, capacity, and metal type.

-

Energy Efficiency: Designed to reduce energy consumption and improve sustainability.

-

Global Support: With a strong network of service centers and engineers, Metcocal ensures you’re never left in the dark.

Applications of Pig Casting Machines Across Industries

While the core function of a Pig Casting Machine remains the same, its applications are vast and varied:

-

Iron and Steel Plants: For casting molten iron from blast furnaces into pig iron.

-

Non-Ferrous Foundries: Aluminum, copper, and other non-ferrous metals are also cast into pig molds for easy transport and remelting.

-

Recycling Facilities: Scrap metal can be melted down and recast into pigs for reuse.

-

Alloy Manufacturing: Pig casting is essential when mixing and standardizing alloys for industrial use.

Metcocal understands the diversity of these applications and offers modular, scalable Pig Casting Machines to match the needs of small workshops as well as large integrated steel plants.

Sustainability and Environmental Considerations

In today’s world, sustainability isn’t just a buzzword; it’s a necessity. Metcocal takes this responsibility seriously by integrating eco-friendly features into its Pig Casting Machines. These include:

-

Closed-Loop Water Systems: Reducing water waste during the cooling process.

-

Dust and Fume Extraction: Ensuring cleaner air and a safer working environment.

-

Energy Optimization: Lower power consumption through advanced drive systems and smart automation.

With regulations around emissions and workplace safety becoming stricter, having a partner like Metcocal ensures you’re always a step ahead of compliance requirements.

Installation and After-Sales Support

Purchasing a Pig Casting Machine is a significant investment, and Metcocal ensures that every step — from consultation to commissioning — is handled with precision. The company offers:

-

Turnkey Installation: From civil works and utility connections to machine commissioning.

-

Operator Training: On-site training to ensure your team knows the ins and outs of the machine.

-

Remote Diagnostics: Most of Metcocal’s machines come with IoT capabilities for real-time monitoring and remote troubleshooting.

-

Spare Parts Availability: Rapid turnaround on spare part delivery keeps downtime minimal.

Looking Ahead – The Future of Pig Casting

With the rise of Industry 4.0, the next generation of Pig Casting Machines is expected to be smarter, more efficient, and even more adaptable. Metcocal is already investing in:

-

AI-Powered Monitoring: Predictive maintenance through AI algorithms to detect wear and tear before breakdowns occur.

-

Integrated Data Analytics: Helping plants understand casting trends and improve yields.

-

Collaborative Robotics: Semi-automated systems where human operators and machines work side by side for even greater control.

In short, Metcocal is not just meeting the present demands of pig casting; it’s actively shaping the future of the industry.

Final Thoughts

The Pig Casting Machine may not be the most glamorous piece of equipment in a foundry, but its importance cannot be overstated. From improving operational efficiency to enhancing worker safety, the right pig casting solution can transform the way your facility functions.

With Metcocal, you’re not just getting a machine — you’re investing in a legacy of quality, innovation, and unwavering customer support. Whether you’re upgrading your current system or starting from scratch, Metcocal’s Pig Casting Machines provide the performance and reliability your operation demands.

Ready to elevate your casting operations? Choose Metcocal — where technology meets trust.