U-bolts are one of the most versatile and widely used fasteners in construction, manufacturing, and various industrial applications. With their unique U-shaped design, these bolts provide unmatched stability and support for pipes, poles, and heavy structures. This blog delves into the details of U-bolts, their applications, types, and why they are indispensable in various industries.

1. What Are U-Bolts?

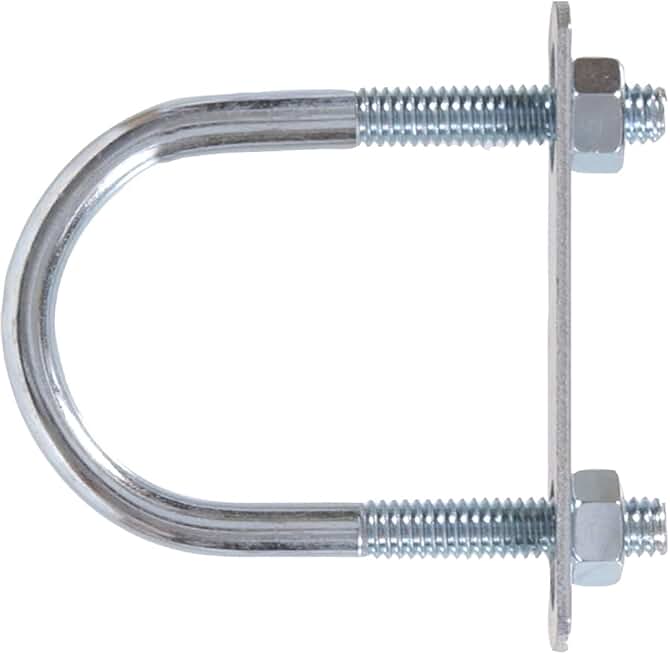

A U-bolt is a fastener with a bent U-shape, featuring two threaded ends. It is designed to wrap around a cylindrical object, such as a pipe, and secure it to a structure. The two threaded arms allow nuts to be fastened, creating a firm hold.

The versatility of U-bolts makes them suitable for securing pipes, conduit, cables, or even as structural supports in buildings and machinery. They are available in various sizes, materials, and finishes, catering to the specific requirements of different industries.

2. Applications of U-Bolts

U-bolts have a broad spectrum of applications, thanks to their strength and durability. Here are some key uses:

a) Pipe and Conduit Support

U-bolts are widely used in plumbing and construction to secure pipes and conduits to walls, ceilings, or floors. They prevent pipes from shifting or vibrating, ensuring safety and efficiency.

b) Vehicle and Trailer Components

In the automotive and transportation sectors, U-bolts are essential for attaching suspension components, securing exhaust systems, and holding leaf springs in place. They ensure stability and alignment, even under heavy loads.

c) Structural Support

In construction projects, U-bolts are used to reinforce beams, poles, and other structural elements. They provide a secure hold, especially in applications requiring resistance to dynamic loads or vibrations.

d) Marine Applications

Due to their corrosion resistance (when made from materials like stainless steel or galvanized steel), U-bolts are commonly used in marine environments. They secure boat components, docks, and other equipment exposed to water and humidity.

e) Industrial Equipment

In industries such as oil and gas, chemical processing, and manufacturing, U-bolts secure heavy machinery, pipelines, and tanks, ensuring safe and efficient operations.

3. Types of U-Bolts

U-bolts come in various designs and materials to suit different applications. Below are the common types:

a) Round U-Bolts

These have a perfect semi-circular bend, making them ideal for securing pipes and cylindrical objects.

b) Square U-Bolts

Square U-bolts feature a 90-degree bend and are used for securing rectangular or flat objects, such as beams or square pipes.

c) Custom U-Bolts

Some applications require custom U-bolts designed to specific dimensions, materials, or coatings. These are typically used in specialized industries like aerospace or marine engineering.

d) Materials and Finishes

- Stainless Steel U-Bolts: Ideal for marine and corrosive environments.

- Galvanized U-Bolts: Provide excellent rust resistance, making them suitable for outdoor use.

- Plain Steel U-Bolts: Commonly used in low-corrosion environments.

- Polymer-Coated U-Bolts: Provide additional protection for sensitive materials and environments.

4. Advantages of U-Bolts

a) Durability

U-bolts are made from high-strength materials, ensuring long-term reliability even under extreme conditions.

b) Versatility

Their simple yet effective design makes them suitable for a wide range of applications, from plumbing to structural engineering.

c) Corrosion Resistance

U-bolts made from stainless steel or with galvanized coatings resist rust and corrosion, ensuring longevity.

d) Ease of Installation

U-bolts are easy to install, requiring only basic tools, which saves time and labor costs.

5. How to Choose the Right U-Bolt

Selecting the appropriate U-bolt is critical to ensuring the success of your project. Consider the following factors:

a) Size

Measure the diameter of the pipe or object being secured and choose a U-bolt with the right size and bend shape.

b) Material

Select a material based on environmental conditions. For example, stainless steel is best for marine environments, while galvanized steel is ideal for outdoor applications.

c) Thread Length

Ensure the threaded ends are long enough to accommodate nuts and washers securely.

d) Load Capacity

Check the load rating of the U-bolt to ensure it can handle the weight and stresses of your application.

e) Coating or Finish

Consider additional coatings, such as polymer or zinc, for applications requiring extra protection against corrosion or wear.

6. Installation Tips for U-Bolts

To achieve the best results, proper installation of U-bolts is essential. Here are some tips:

- Position the U-Bolt Correctly: Ensure the bolt wraps around the object snugly without gaps.

- Use Appropriate Washers and Nuts: Use flat washers and locknuts to distribute load evenly and prevent loosening due to vibrations.

- Tighten Evenly: Tighten the nuts on both sides evenly to avoid misalignment or stress on one side.

- Avoid Over-Tightening: Over-tightening can damage the threads or deform the U-bolt.

7. The Role of a Reliable Supplier

A trustworthy U-bolt supplier ensures you get high-quality fasteners that meet your project’s requirements. Whether you need standard U-bolts or custom designs, choosing the right supplier can make a significant difference in the success of your application.

Look for a supplier that offers:

- A wide range of U-bolt sizes and materials.

- Customization options for specific applications.

- Competitive pricing and reliable delivery.

Conclusion

U-bolts are simple yet essential fasteners that play a critical role in securing pipes, machinery, and structural components. Their strength, versatility, and durability make them indispensable across industries. By choosing the right type of U-bolt and sourcing it from a reputable supplier, you can ensure long-lasting and reliable performance for your projects.

Whether you’re a contractor, manufacturer, or DIY enthusiast, understanding the applications and benefits of U-bolts will help you make informed decisions and achieve optimal results.